Round Manhole Cover

Product Details:

Round Manhole Cover Price And Quantity

- as per requirment Piece

Round Manhole Cover Trade Information

- Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Yes

- Contact us for information regarding our sample policy

- standard

- All India

- ISO 9001-2008,ISI12592

Product Description

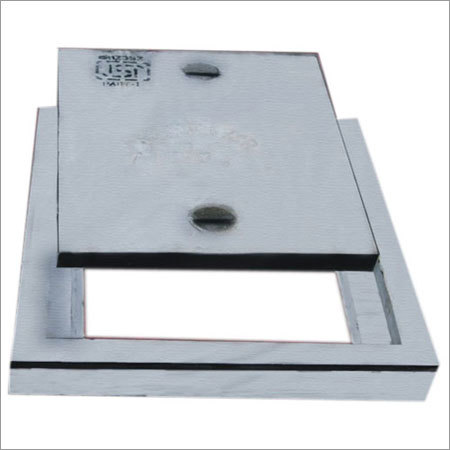

Our consistent efforts and dedication enable us to carve a niche as a most trustworthy organization engaged in offering Round Manhole Cover. This cover is used for covering and laying over drain in streets and highways. Our expert workforce uses quality grade materials to manufacture this cover. Available in different sizes and designs, this cover is highly demanded among clients. We offer this Round Manhole Cover at market leading prices to clients.

Features:

- Rugged construction

- Easy to install

- Breakage free

Further Details:

The Precast concrete manhole covers & frames were introduced to the construction industries due to the necessity of suitable alternative to cast iron manhole covers & frames. The cost of cast iron is increasing day by day and cast iron manhole covers are prone to pilferage and misuse since they possess a high resale value, causing financial loss due to the need for replacement of stolen covers, accidents due to the open manholes and other environmental problems. Precast manhole covers & frames are found to satisfy the basic requirements and are also found to be economical substitute to cast iron manhole covers & frames, and these concrete cover & frame are gaining fast popularity and are being used everywhere in sewerage and water works.

Merits of precast concrete manhole cover / Frame over CI cover / Frame.

|

Characteristics |

C I Covers |

Precast Concrete Covers |

|

Durability |

Brittle |

Highly Durable |

|

Strength |

Equal |

Equal |

|

Susceptibility to Thefts |

High |

Nil |

|

Scrap Value |

High |

Very Low |

|

Cost |

100 % |

40 % |

Grade and Types

Manhole Covers and frames shall be of the following four grades and types:

|

Grade |

Grade Designation |

Type/Shape of Cover |

|

Light Duty |

LD-2.5 |

Rectangular, Square, Circular |

|

Medium Duty |

MD-10 |

Rectangular, Square, and Circular |

|

Heavy Duty |

HD-20 |

Rectangular (Scrapper Manhole), Square, Circular and Lamphole |

|

Extra Heavy Duty |

EHD-35 |

Rectangular (Scrapper Manhole), Square and Circular |

Recommended Locations for Placement :

- Light Duty (LD-2.5) : Suitable for use with in residential and institutional complexes / areas with pedestrian but occasional light motor vehicle traffic. These are also be used for "Inspection chambers."

- Medium Duty (MD-10) : Suitable for use in service lanes / roads, on pavements for use under medium duty vehicular traffic including for car parking areas.

- Heavy Duty (HD-20) : Suitable for use in institutional / Commercial areas / carriageways / city trunk roads / bus terminals with heavy duty vehicular traffic of wheel load between 50 to 10 kN, like buses, trucks and parking areas and where the manhole chambers are located in between the pavement and the middle of the road.

- Extra Heavy Duty (EHD-35) : Suitable for use on carriageway in commercial / industrial /port areas / near warehouses / godowns where frequent loading and unloading of trucks / Trailers are common, with slow to fast moving vehicular traffic of the types having wheel loads up to 115 kN irrespective of the location of the manhole charmers.

- Man-hole cover & frames are available in various sizes and shapes covered under IS:12592. The size other than covered under IS: 12592 can also manufacture depending upon the requirements of customer.

Material

The raw materials are being used in manufacture of Precast Concrete Manhole cover and frame are according to the specification of IS v12592 : 2002.

- Cement : Cement used for the precast concrete manhole covers shall confirm to IS 269 or IS 455 or IS 1489 (Part 1) or IS 1489 (Part 2) IS 8041 or IS 8043 or IS 8112 or IS 12330 or IS 12269.

- Aggregates The aggregates are well graded. The nominal maximum size of coarse aggregate is not exceeding 20mm, which confirms to the requirements of IS 383.

- Concrete : The minimum cement content in the concrete shall be 360 Kg / m3, with a maximum water cement ratio of 0.45. Concrete weaker than grade M-30 is not be used. Compaction of concrete shall be done by machine vibration.

- Water : The water is free from matter harmful to concrete or reinforcement and according to the requirements of IS 456.

- Reinforcement : Reinforcement used shall be clean and free from Loose mill scale, loose rust, mud, oil, grease or any other coating which may reduced or destroy the bond between concrete and steel, further it shall confirm to Grade A of IS 2062 or IS 432 (part 1) or IS 432 (part 2) or IS 1786.

- Steel Fibres : The steel fibres where use not be greater than 0.75 mm in diameter / equivalent diameter. The minimum volume of fibers are be 0.5 percent of the volume of concrete.

- Admixtures : If admixture used, it shall confirm to IS 9103.

- Design The reinforced concrete manhole cover and frame are designed in according to IS 456.

- Dimensions and Tolerances : The dimensions and tolerance on dimensions of frame confirming to Table 1 of IS 12592 : 2002 but outside dimensions of cover at top is match with the corresponding frame so that the maximum clearance at top between the frame and the cover all round the periphery is not more than + 5mm and the top surface of the frame and cover is in level within a tolerance of 5mm.

Manufacture :

- Mixing : Concrete are mixed in a mechanical mixer to ensure uniform distribution of materials and the mesas is uniform in colour and consistency.

- Placing And Compaction : The reinforcement is placed in proper position in moulds coated with a thin layer of mould oil in case of frames and within the protective sheet in case of covers. Concrete is filled to slightly overfill the mould and compacted by vibration and struck off level with a trowel. Table vibrator is used for compaction.

Clear cover to reinforcement is maintained not less than 15 mm. - Demoulding : After de3moulding, cover and frame are protected until they are sufficiently hardened to permit handling without damage.

- Curing : The hardened concrete manhole cover and frame are placed in a curing water thank the period of curing according to IS 456.

Finishing

- Covers : The underside of covers is treated with anti-corrosive paint to prevent any possible damage from corrosion. The top surfaces of the covers are given a chequered finish. The covers are casted with a protective mild steel sheet of minimum 2 mm thickness around the periphery of the covers to protect the edges of the covers from possible damage at the time of lifting and handling.

- Frame : The top outer edge of the frames is protected by 25 mm x 3 mm mild steel flat as part of the frame to prevent from possible damages. The exposed surface of the mild steel flat is given suitable treatment with anti-corrosive paint or coating.

- Load Test : The load test on manhole covers is performed by a suitable arrangement to determine the load bearing capacity of a cover. The cover is supported in a standard frame. After putting cover in standard frame the specified load is applied without shock through the medium of a bearing block, for a minimum period of 30 + 2 seconds and increased gradually till the cover breaks.

The maximum load which the manhole cover withstands without fracture for a minimum period of 30 seconds is reported as the breaking load.

The breaking load of individual covers when tested is not less than the values specified in Table.

|

Grade of Cover |

Type |

Diameter of Block (mm) |

Load (kN) |

|

EHD-35 |

Rectangular, square of circular |

300 mm |

350 |

|

HD-20 |

Rectangular, square of circular |

300 mm |

200 |

|

MD-10 |

Rectangular, of circular |

300 mm |

100 |

|

LD-2.5 |

Rectangular, square of circular |

300 mm |

25 |

All the tests are conducted on samples of covers and frames are confirming to IS 12592 : 2002, The number of covers and frames required for the test are taken at random basis.

Sampling Nad Inspection

For the conformity of the materials in the lot to the requirements of this specification, samples are tested from each lot separately. The number of cover and frames to be selected from the lot are depend on the size of the lot and are according to given table.

|

No. of Covers or Frame in the lot |

Dimensional Requirements |

No. of samples for load Test on cover only |

|

|

Sample size |

Acceptance Number |

||

|

Up to 100 |

10 |

1 |

2 |

|

101 to 200 |

15 |

1 |

3 |

|

201 to 300 |

20 |

2 |

4 |

|

301 to 500 |

30 |

3 |

5 |

The number of covers and frames with dimensions outside the tolerance limit and or with visual defects among those inspected shall be less than or equal to the corresponding acceptance number given in column 3 of table.

Product Range :

|

Product Description |

Grade Designation |

Shape |

Clear Opening in Frame |

Frame Size |

Cover Size |

||||

|

B |

C |

D |

E |

Thickness |

Diameter of Cover |

||||

|

Light Duty |

LD-2.5 |

Square |

450 x 450 |

50 |

50 |

50 |

50 |

50 |

566 |

|

Light Duty |

LD-2.5 |

Rectangular |

450 x 600 |

50 |

50 |

50 |

50 |

50 |

570 x 720 |

|

Light Duty |

LD-2.5 |

Circular |

450 |

50 |

50 |

50 |

50 |

50 |

566 |

|

Light Duty |

LD-2.5 |

Circular |

560 |

50 |

50 |

50 |

50 |

50 |

676 |

|

Medium Duty |

MD-10 |

Square |

600 x 600 |

70 |

50 |

50 |

50 |

70 |

720 x 720 |

|

Medium Duty |

MD-10 |

Rectangular |

450 x 600 |

70 |

50 |

50 |

50 |

70 |

570 x 720 |

|

Medium Duty |

MD-10 |

Circular |

500 |

70 |

50 |

50 |

50 |

70 |

620 |

|

Medium Duty |

MD-10 |

Circular |

560 |

70 |

50 |

50 |

50 |

70 |

680 |

|

Medium Duty |

MD-10 |

Circular |

600 |

70 |

50 |

50 |

50 |

70 |

720 |

|

Heavy Duty |

HD-20 |

Square |

560 x 560 |

90 |

50 |

50 |

50 |

90 |

740 x 740 |

|

Heavy Duty |

HD-20 |

Rectangular |

450 x 900 |

90 |

75 |

75 |

75 |

90 |

630 x 1080 |

|

Heavy Duty |

HD-20 |

Circular |

500 |

90 |

75 |

75 |

75 |

90 |

680 |

|

Heavy Duty |

HD-20 |

Circular |

560 |

90 |

75 |

75 |

75 |

90 |

740 |

|

Heavy Duty |

HD-20 |

Circular |

600 |

90 |

75 |

75 |

75 |

90 |

780 |

|

Extra Heavy Duty |

EHD-35 |

Circular |

560 |

100 |

75 |

75 |

75 |

100 |

738 |

|

Extra Heavy Duty |

EHD-35 |

Circular |

600 |

100 |

75 |

75 |

75 |

100 |

778 |

|

All Above Precast Concrete Cover can also be provided with suitable hole as per customer requirement for rain water drainage |

|||||||||

Note :

- Tolerance on C shall be +5 mm.

- Tolerance on A, B, D, and E are +5, -0 mm